Silicone Dissolver/Cleaning Agent・Resin Dissolver

【Effect Verification Video】How to dissolve hardened silicone

Silicone Dissolver Selection

| Product | Main Components | Appearance | Flash Point | 適用法廷 | |||

|---|---|---|---|---|---|---|---|

| 危険物 | 有機則 | 毒劇物 | PRTR | ||||

| SILICONECLEANER X-100 | Hydrocarbons Surfactants |

Dark Reddish Brown Liquid | 45℃ | 4-2 水溶 |

非 | 非 | 2種 |

| SILICONECLEANER X-400 | Fluorine-based Solvents Surfactants |

Dark Brown Liquid | None | 非 | 非 | 非 | 非 |

[Uses and Usage History]

*Silicone adhesive peeling and removal

*Removal of silicone sealant and water-stopping material

*Removal of insulating sealant (for failure analysis)

*RTV/liquid silicone rubber jig cleaning

*Cleaning silicone release agents for molds

*Cleaning of silicone rubber molding machines

*Coater cleaning for the production of release films and release papers

It is currently on sale at the Nissin Chemical Laboratory official online store, "Nissin Chemical Lab." Please click here to purchase.

Please download the SDS here.

Silicone Oil Cleaner Selection

| Product | Main Components | pH(1%) | Applicable Temperature | 適用法令 | |||

|---|---|---|---|---|---|---|---|

| 危険物 | 有機則 | 毒劇物 | PRTR | ||||

| SILICONECLEANER AQ-10 | Surfactants Glycol Compounds Alkaline Agent |

11.0~13.0 | 25℃~40℃ | 非該当 | 非該当 | 非該当 | 非該当 |

| SILICONECLEANER AQ-20 | 60℃~80℃ | 非該当 | 非該当 | 非該当 | 非該当 | ||

[Uses and Usage History]

*Cleaning silicone oil stains from manufacturing vessels

*Cleaning silicone oil-containing cosmetics from tanks

※Silicone resin cannot be dissolved with the "Silicon Cooner AQ Series".

For dissolving silicone resin, please refer to the "Silicon Cleaner X Series".

The catalog is posted on the manufacturing technology database site "IPROS." Please download it from here.

Resin Dissolving Agent Selection

| Product | Optimal Resin | Boiling Point First Station |

Flash Point | 適用法令 | |||

|---|---|---|---|---|---|---|---|

| 危険物 | 有機則 | 毒劇物 | PRTR | ||||

| レジンクリーナーGU-100 | PAc、EVA | 195℃ | 110℃ | 4-3 非水 |

非 | 非 | 非 |

| レジンクリーナーUS-100 | EVA、PU、PC、PVC | 204℃ | 99℃ | 4-3 水溶性 |

非 | 非 | 1種 |

| レジンクリーナーHF-300 | EVA、PU、PC、PVC | 54℃ | None | 非 | 非 | 非 | 非 |

| レジンクリーナーET-200 | PET、PU | 59℃ | None | 非 | 非 | 非 | 非 |

| レジンクリーナーEX-200 | Si、PU、 Epx、PC、NY66 |

54℃ | None | 非 | 非 | 非 | 非 |

| レジンクリーナーAS-60 | Painting, Resist Stripping, etc. | 100℃ | None | 非 | 非 | 非 | 1種 |

※PAc=Polyacrylic Acid Ester, EVA=Polyethylene Vinyl Acetate, PU=Polyurethane、PUE=Unsaturated Polyester, Epx=Epoxy, UV=UV Curing Type

PC=Polycarbonate, PVC=Polyvinyl Chloride, NY66=6,6-Nylon, PET=Polyethylene Terephthalate, Si=Silicone Resin

[Uses and Usage History]

*Dissolving and cleaning away adhesives and glues

*Cleaning mold deposits from molding machines

*Cleaning of resin molding machines and resin molds

*Removal of insulating sealant (for failure analysis)

*Cleaning of coating and painting equipment and jigs

*Paint and coating resin peeling

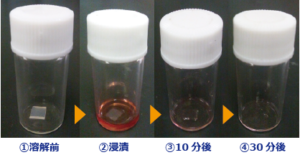

[Usage example]

1. Immerse the part you want to dissolve in the undiluted resin cleaner.

2. If you want to speed up the dissolution process, it is effective to heat the area to less than 40°C or use physical treatments such as stirring, brushing, and ultrasonic treatment.

3. After dissolving, remove the residue with a rag or rinse with water, an organic solvent, or detergent.

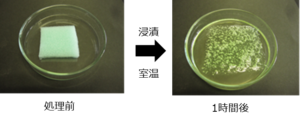

[Dissolving Urethane Resin Sponge]

The catalog is posted on the manufacturing technology database site "IPROS." Please download it from here.

Product Features

*SILICONECLEANER

1. Powerfully breaks down siloxane bonds (-Si-O-Si-).

2. It also dissolves and softens hardened silicone resin, making it removable.

3. It does not contain chlorine-based solvents or aromatic solvents such as toluene and xylene, so it has little odor and can be used safely.

4. It is water-soluble, so it can be washed off with water.

*RESINECLEANER

1. It can soften and dissolve various resins, making them easier to peel off and remove.

2. It does not attack metal, glass, ceramic, or other substrates.

3. It does not contain chlorine-based solvents or aromatic solvents such as toluene and xylene, so it has little odor and can be used safely.

4. It is water-soluble, so it can be washed off with water.

5.各種法規制(毒劇物、労安法有機側、PRTR法)には非該当ですので、安心してご利用できます。

[How to use]

*Immerse the area you want to dissolve in undiluted silicon cleaner/resin cleaner.

*If you want to speed up the dissolution process, it is effective to heat the area to less than 40°C or use physical treatments such as stirring, brushing, and ultrasonic treatment.

*After dissolving, remove the residue with a rag or rinse with water, an organic solvent, or detergent.